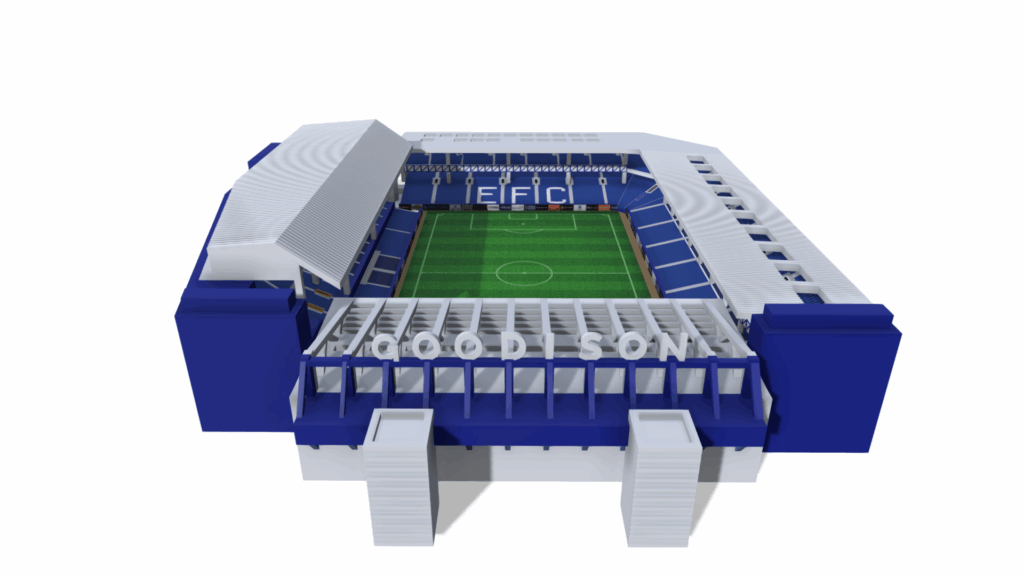

Design and production of Stadium models

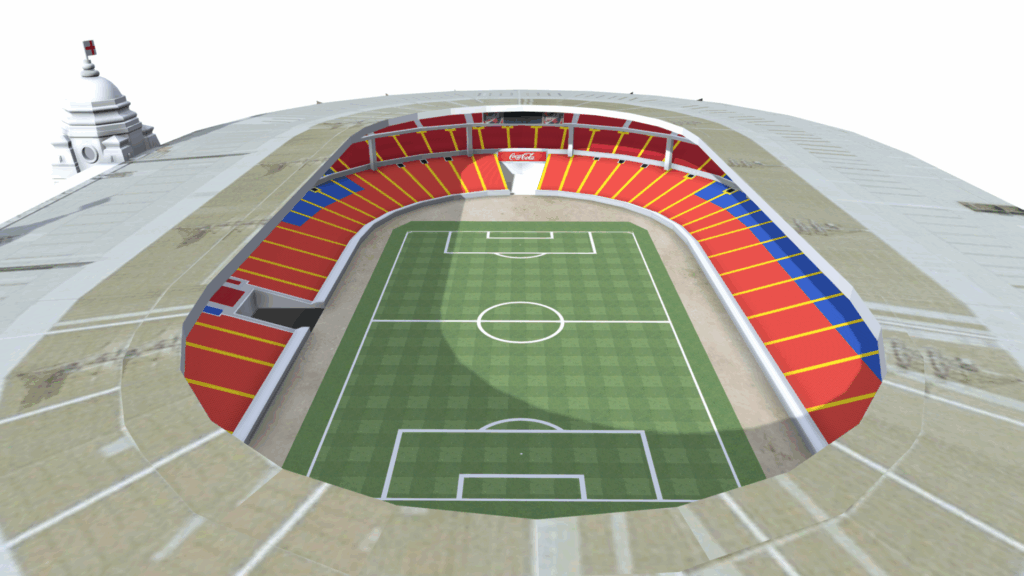

Creating a stadium model is a blend of architectural accuracy, digital craftsmanship, and advanced manufacturing. Every model we produce goes through a carefully considered process to ensure it captures the character, scale, and atmosphere of the real venue.

1. Research & Reference Gathering

Every stadium begins with deep research.

We collect and analyse:

- Architectural plans and drawings (where available)

- High-resolution photographs from multiple angles

- Aerial imagery and site context

- On-site visits to understand scale, materials, and spatial relationships

This stage allows us to go beyond surface detail and understand how the stadium truly works as a structure and as a place.

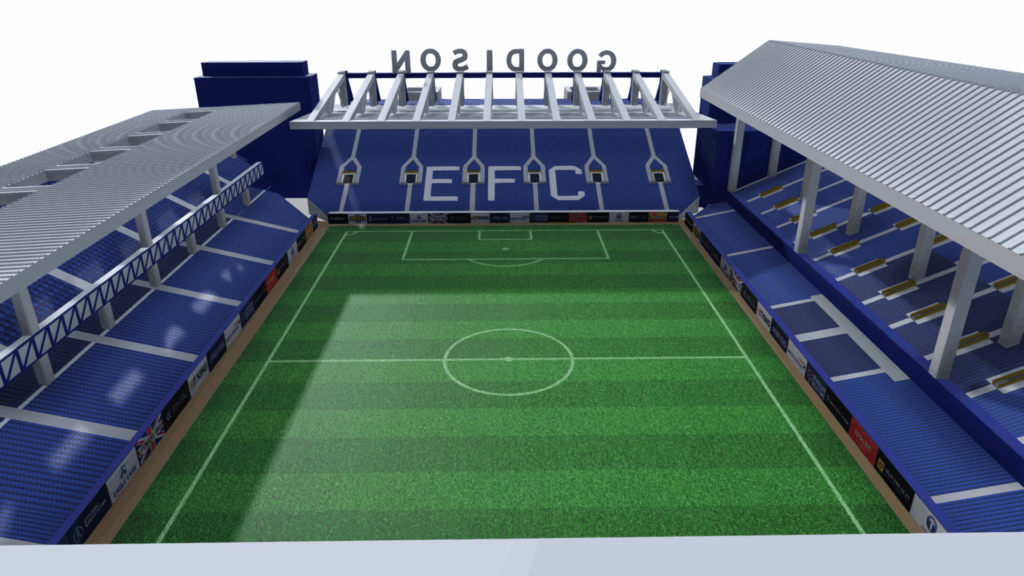

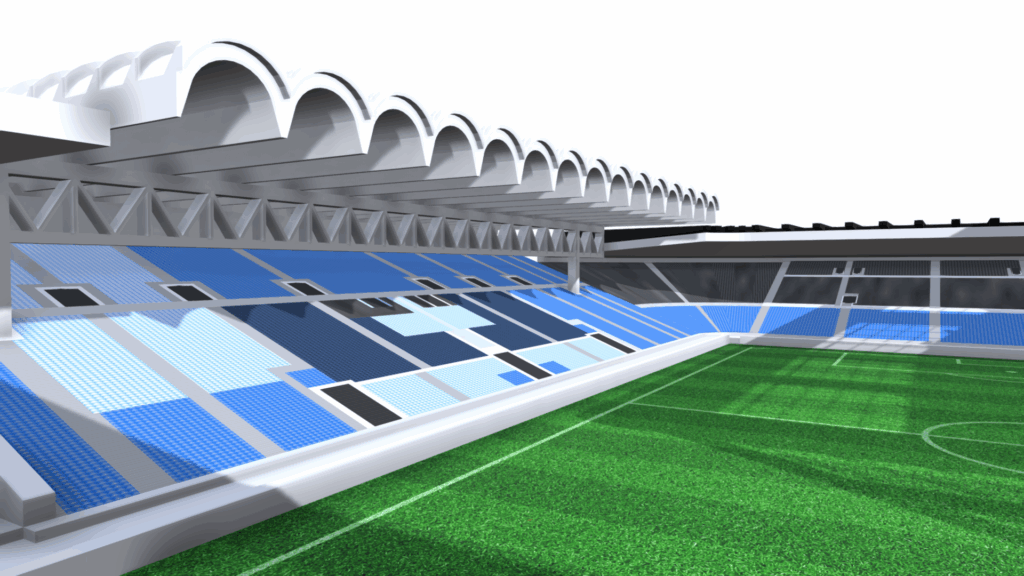

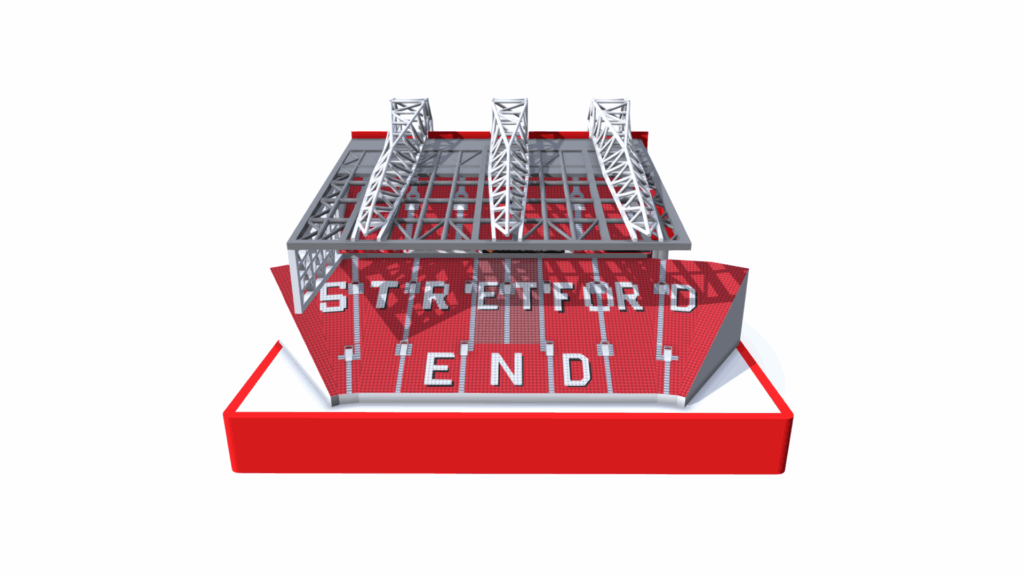

2. Advanced CAD Design

Using professional-grade architectural and engineering CAD software, we translate real-world data into a precise digital model.

This includes:

- Accurate geometry and proportions

- Structural forms such as stands, roofs, and façades

- Key architectural features that define the stadium’s identity

Models are designed with both visual accuracy and manufacturability in mind, ensuring they can be assembled cleanly while retaining detail.

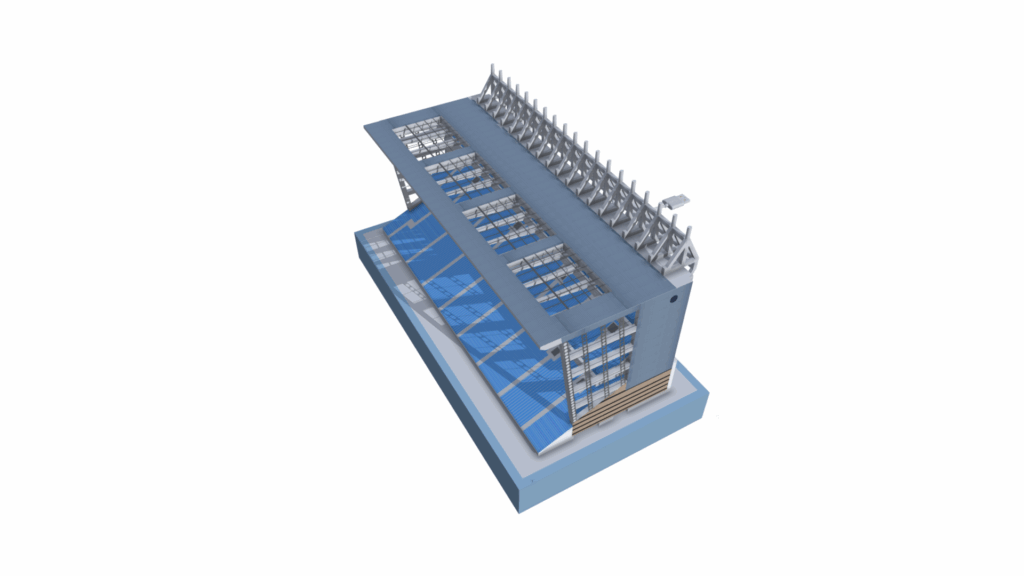

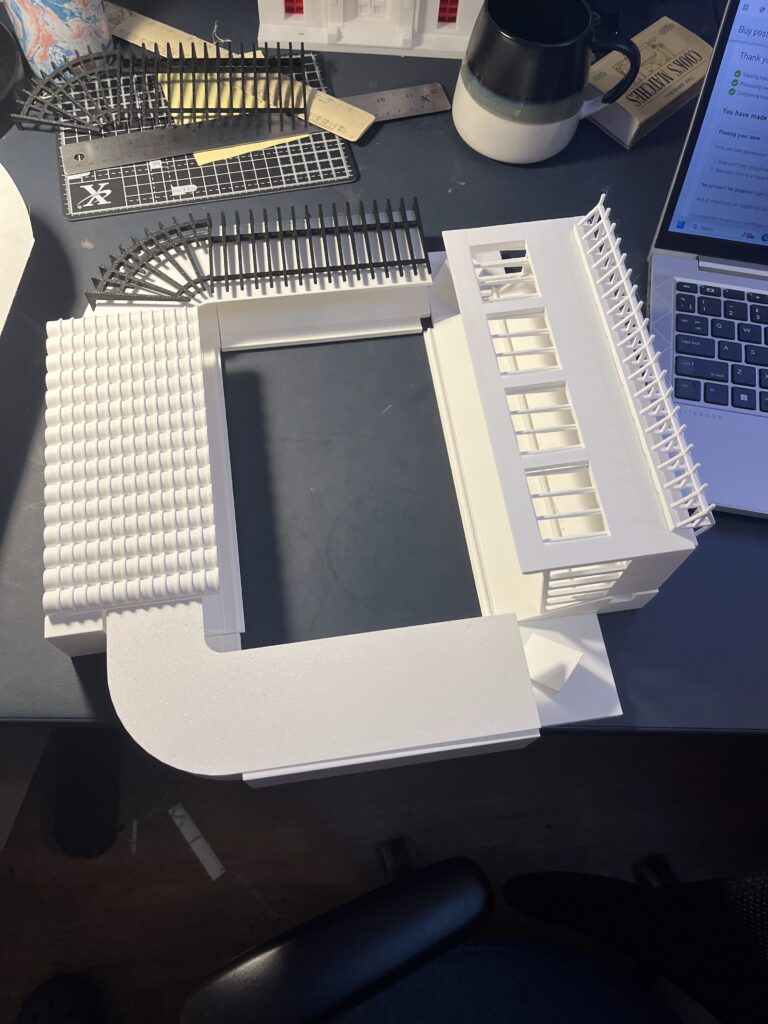

3. Digital Prototyping & Testing

Before anything is produced physically, the digital model is tested and refined.

We:

- Break the stadium into logical build sections

- Test assembly sequences digitally

- Adjust tolerances for real-world materials

- Optimise wall thickness and connection points

This ensures each model is buildable, durable, and enjoyable to assemble.

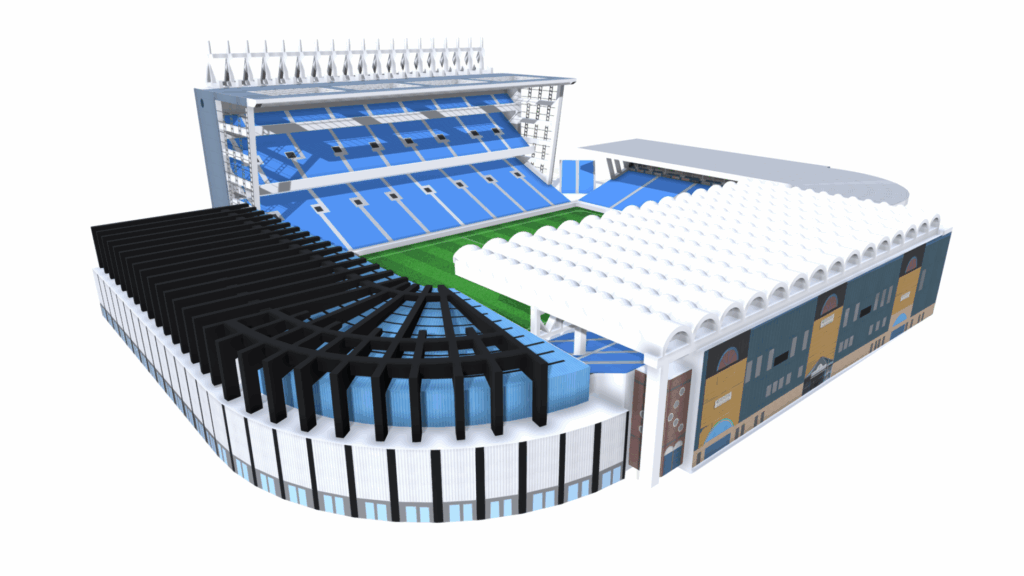

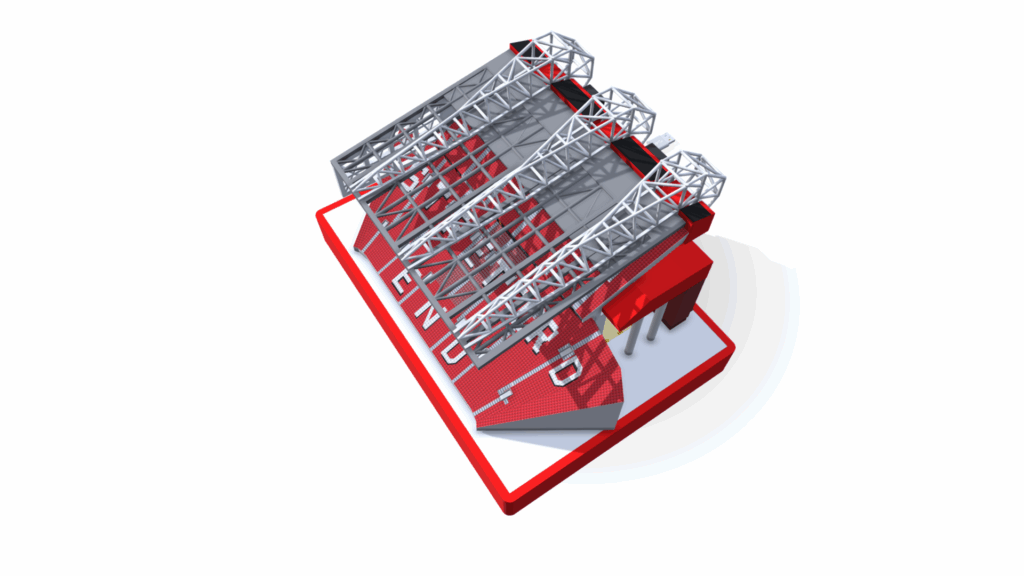

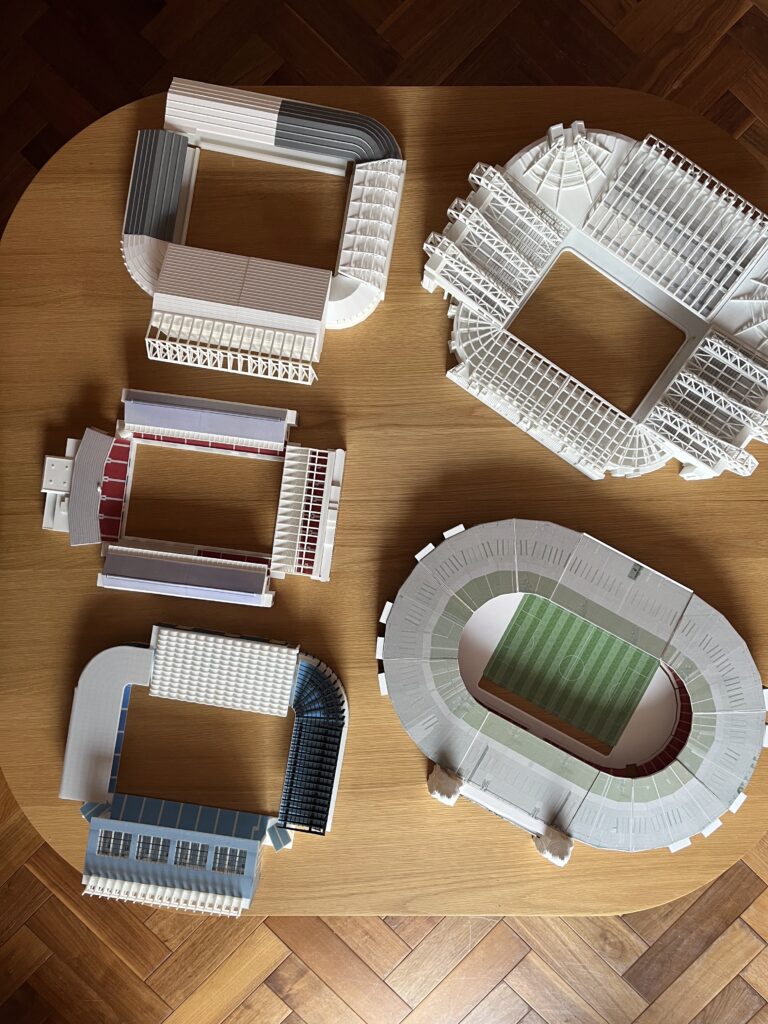

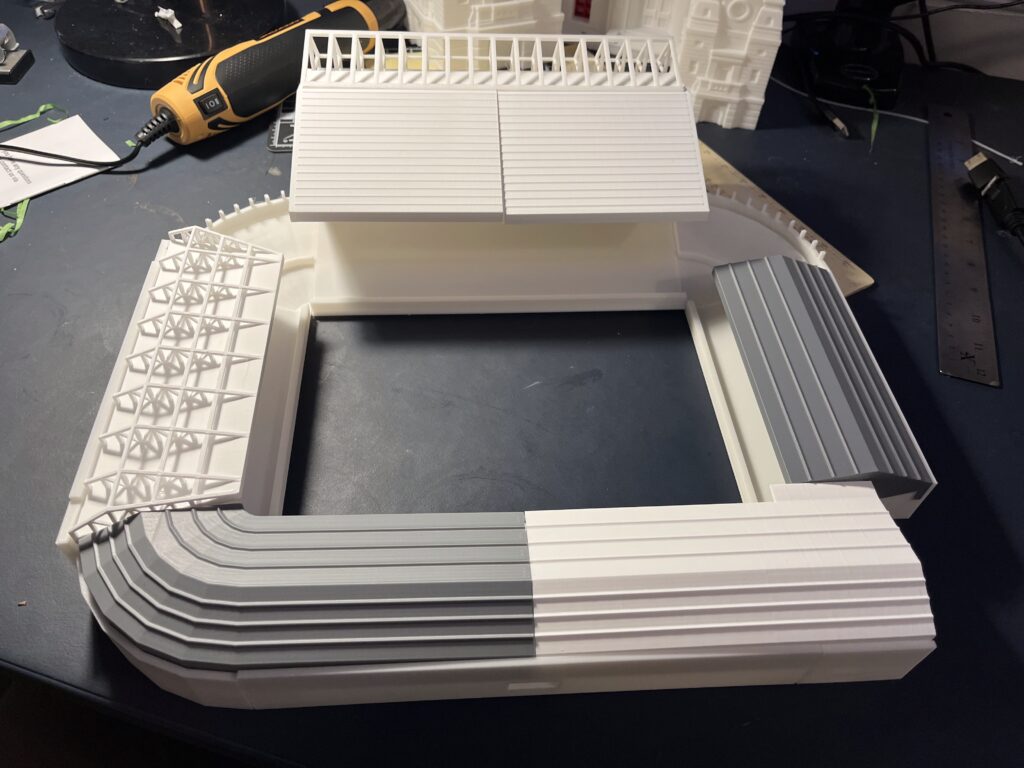

4. High-Tech Manufacturing

Once the design is finalised, production begins using advanced manufacturing methods.

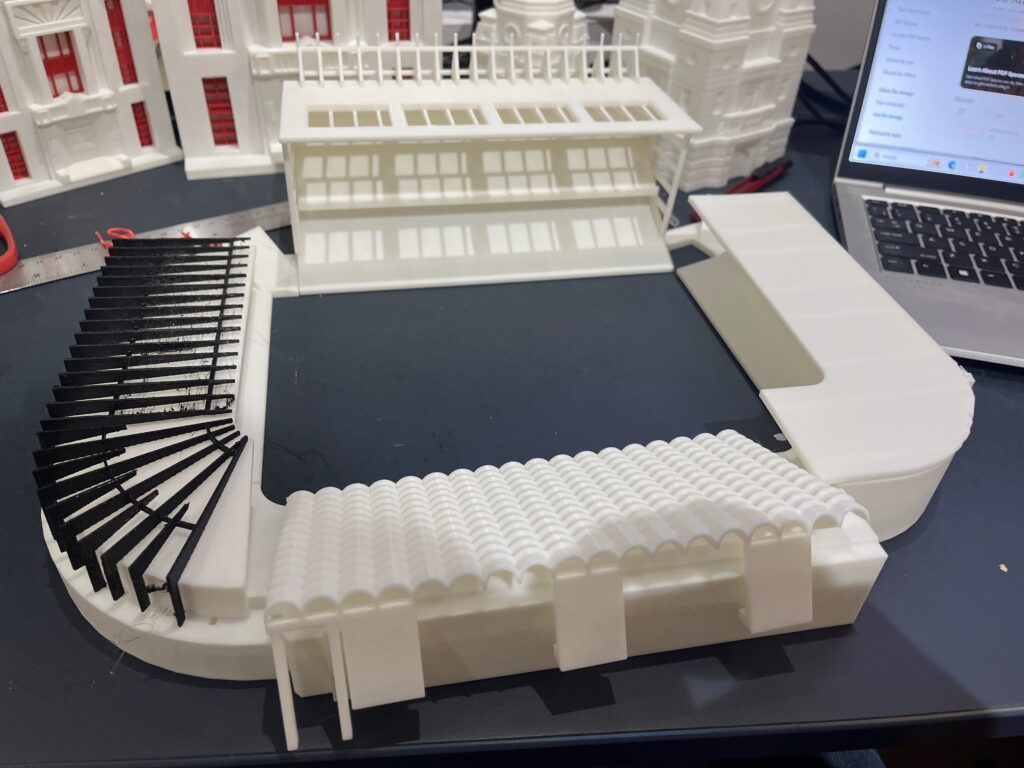

Precision 3D Printing

We use high-resolution industrial-grade 3D printing to produce:

- Structural components

- Detailed architectural features

- Seating tiers, roof elements, and façades

This allows us to achieve levels of detail not possible with traditional moulding methods.

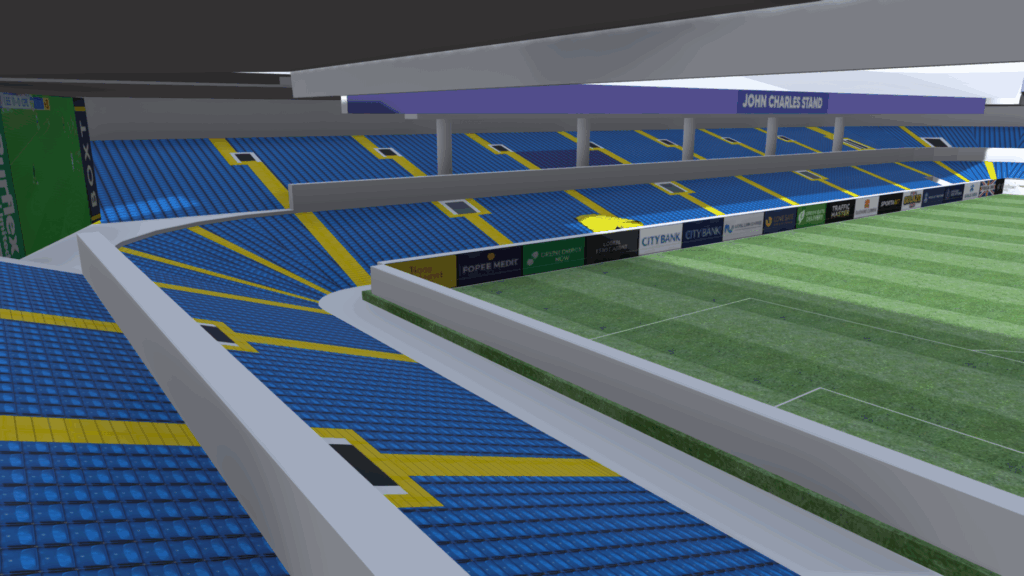

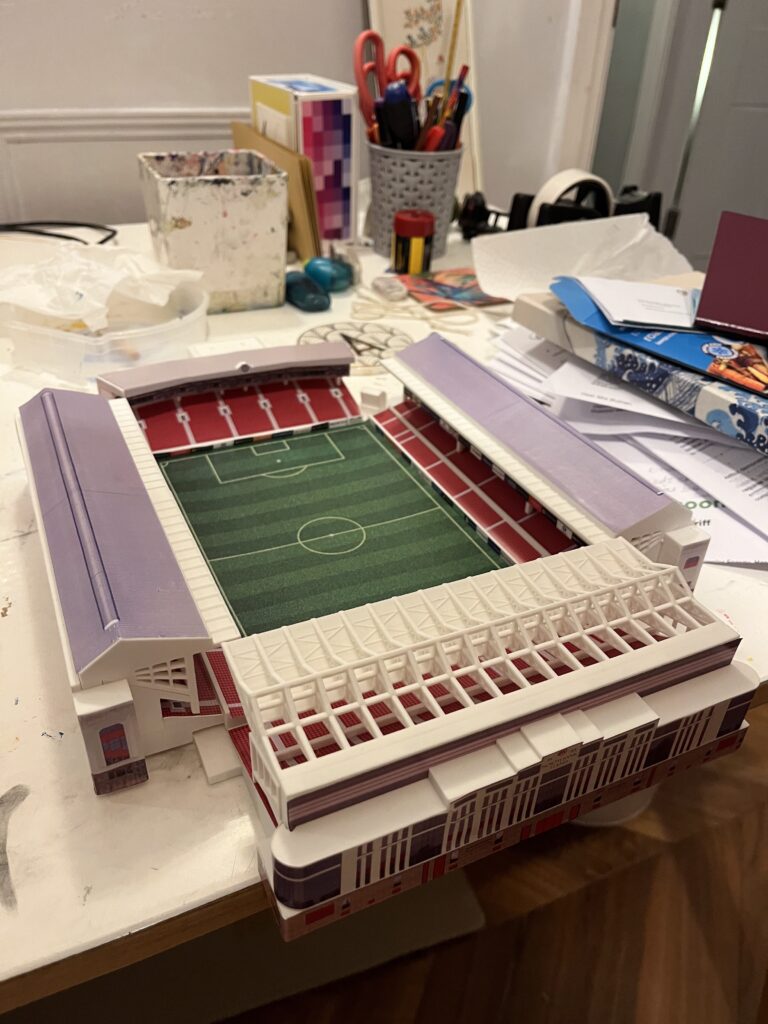

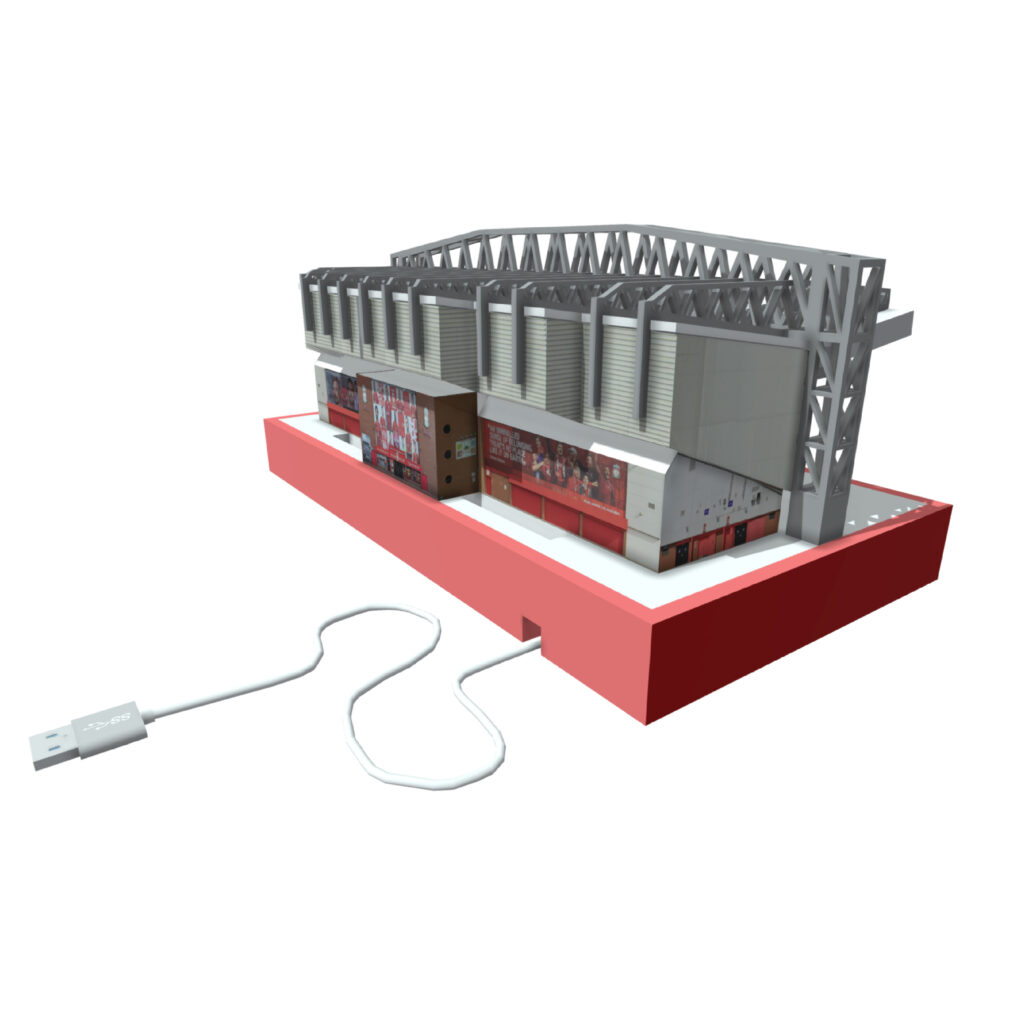

Custom Graphics & Sticker Production

To bring the stadium to life, we design and produce:

- Pitch markings

- Seating patterns

- Sponsor boards and signage

- External branding elements

These are printed using high-quality materials to ensure clarity, colour accuracy, and long-term durability.

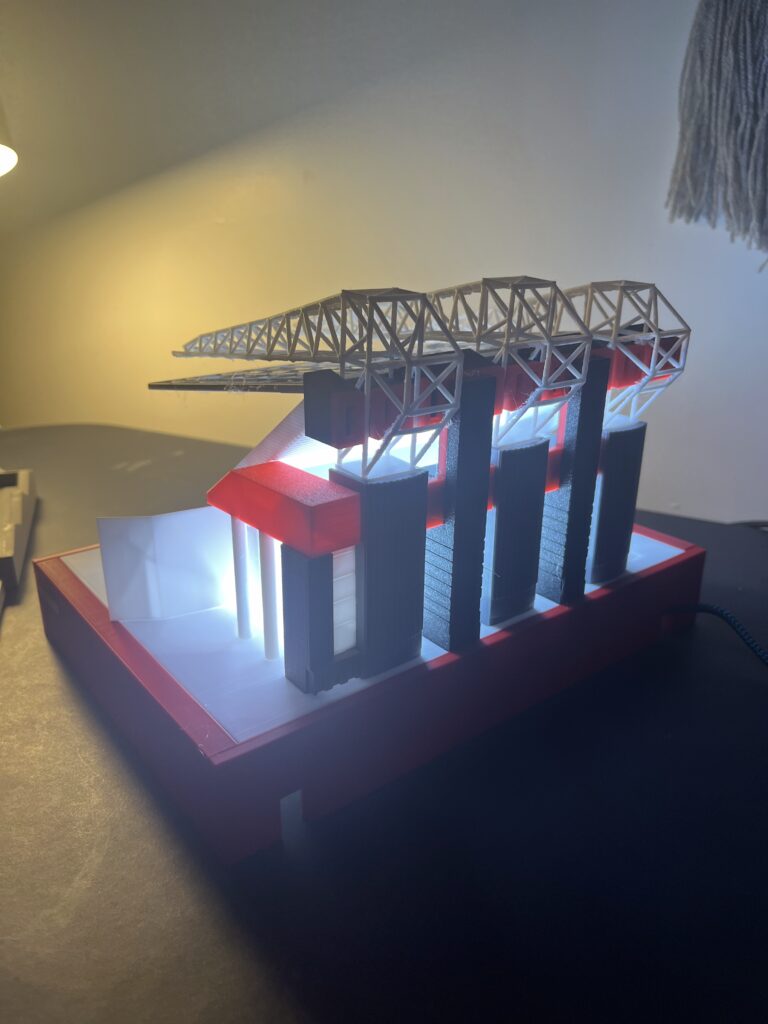

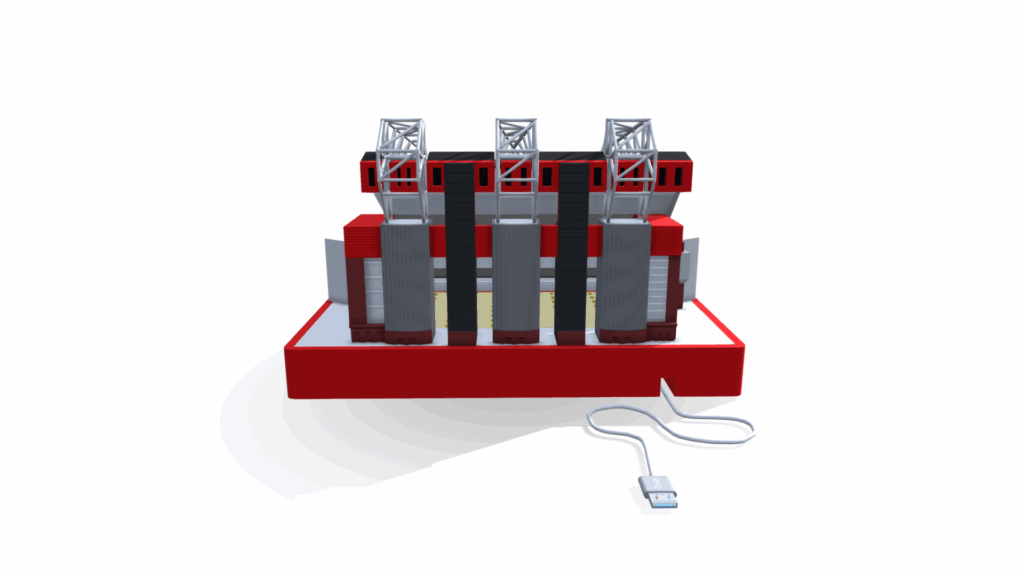

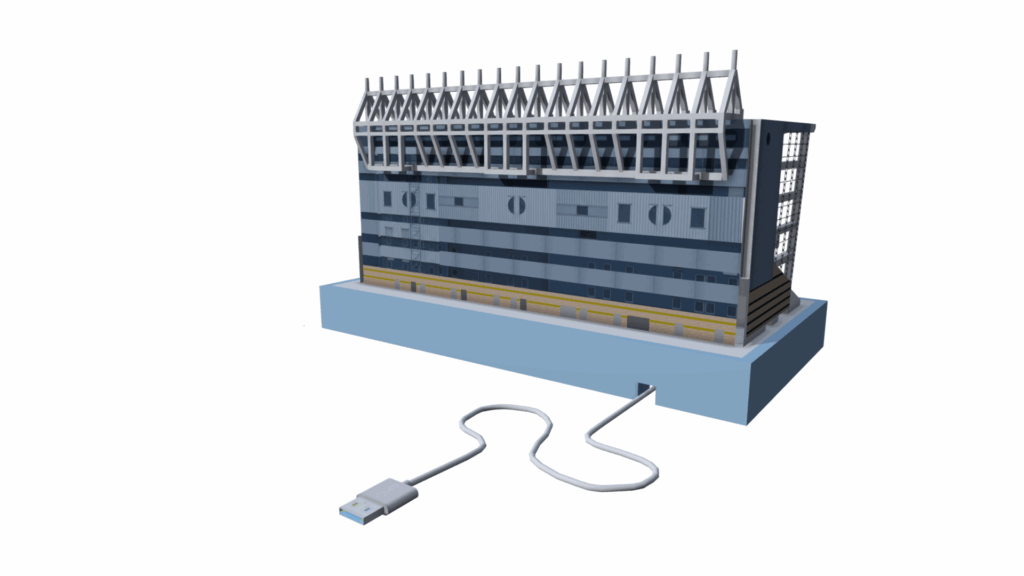

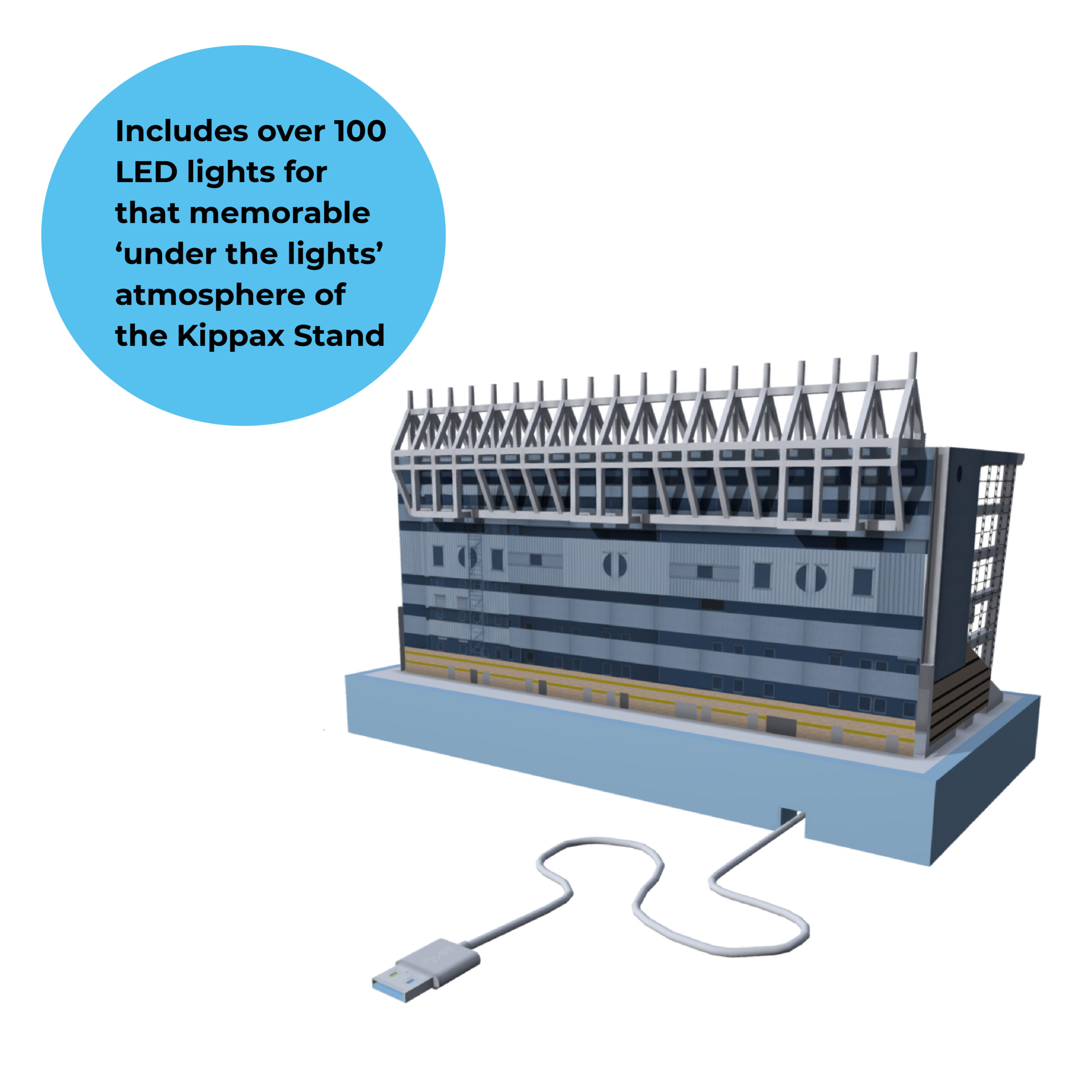

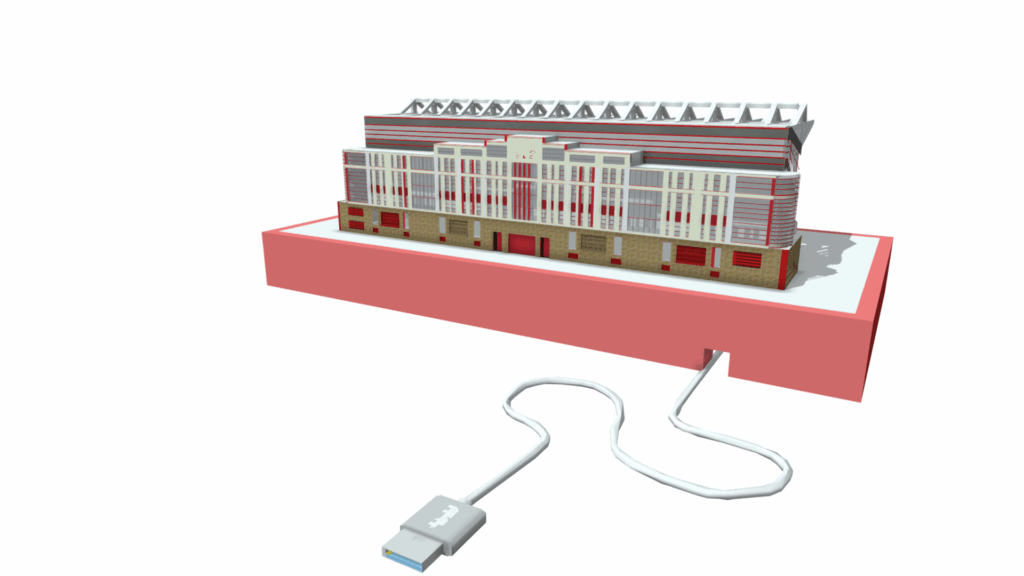

Integrated Lighting Engineering (Selected Models)

For certain stadium models, we incorporate engineered lighting systems.

This includes:

- Low-voltage LED lighting

- Concealed cable routing designed into the model

- Even light distribution across seating and concourses

Lighting is planned during the CAD stage to ensure it integrates seamlessly into the structure.

5. Quality Control & Kit Preparation

Every model is checked before packing.

We ensure:

- Parts fit correctly and assemble as intended

- Printed components meet quality standards

- Graphics align accurately with physical elements

- Kits are complete and clearly organised

Models are then packaged as build-at-home kits, ready for assembly.

6. Designed to Be Built

Our stadium models are created not just to be displayed, but to be built.

Clear design, logical assembly, and carefully considered components mean the build process is:

- Structured

- Enjoyable

- Accessible to hobbyists

The result is a finished model that feels both technically impressive and personally rewarding.

Precision. Passion. Place.

From architectural plans to a finished display piece, every stadium model is designed to honour the place it represents. We combine architectural thinking with modern manufacturing to create models that celebrate sport, structure, and memory.